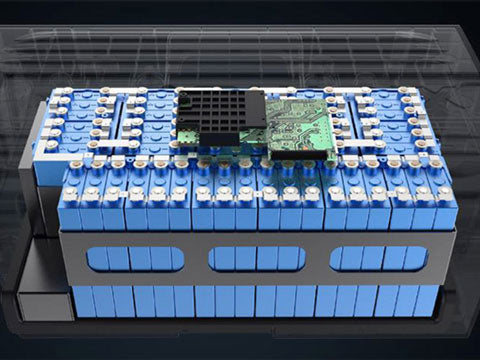

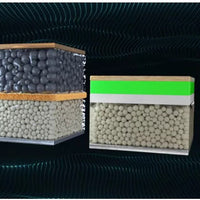

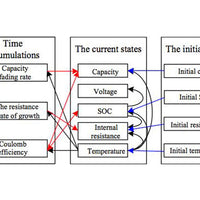

The battery pack of new-energy vehicles is usually composed of many lithium batteries cells. There are two key indicators for the investigation of cells: one is the capacity of the cell, which can be regarded as the capacity of a bowl; the other is the charged state of the cell (commonly known as the remaining electric quantity, hereinafter referred to as SOC), which can be regarded as the water content in the bowl.

However, with the increase of service life and charging times, the capacity or SOC of each cell will inevitably change in the battery. According to the principle of a wooden barrel, the amount of water that a flat wooden barrel can hold is determined by the shortest plate, so is the capacity of the lithium battery pack.

The key factors of a lithium battery performance is a very big one part is that each of these batteries consistency, in layman's terms, if bad consistency of lithium battery set into a battery pack, probably in the process of normal discharge, when most of the battery to be able to work effectively, the individual battery because power is not enough to form a discharge, dragging on the lithium battery can't work.

The condition of "inconsistent battery cells" should be improved by the BMS lithium battery management system. The most important "treatment process" is "balanced battery" or "balanced battery repair". BMS is a lithium battery management system. Its main function is to detect various state parameters of the power battery, including single voltage, total voltage, current, temperature, etc., and to perform SOC estimation and battery balancing by simulating the front-end data collection.

The concept of cell balance is believed to have been touched by all of us, mainly because the current cell consistency is not good enough, and it needs to be improved through balance. It is similar to that you cannot find two identical leaves in the world, neither can you find two identical cells. So in the final analysis, equilibrium is to solve the shortcomings of the cell, is a means of making up.

BMS lithium battery management system is mainly used in lithium batteries as power system of electric vehicles, electric boat, electric equipment, total monomer batteries inside the lithium battery voltage, battery parameters such as pressure, the temperature of batteries, battery charge and discharge current for real-time monitoring and provide corresponding batteries balance management, charge and discharge protection control, heating refrigeration and fault alarm information.

Features of the lithium battery management system

- Real-time display of total battery voltage, total battery current, single battery voltage, single battery minimum voltage, average voltage, single internal resistance, temperature, equilibrium state, capacity, etc.;

- By on-line measuring the total voltage of lithium battery pack and the voltage of the single battery, analyzing the difference between the single battery pack and carrying out voltage balance automatically, the performance attenuation caused by individual single battery pack can be effectively reduced and the service life of battery pack is close to the design life of the battery.

- The module has powerful functions. Each module monitors the voltage, internal resistance, and balanced management of 12 lithium batteries and the temperature of one circuit. It adopts down-mounted installation and dual-line acquisition to improve the test accuracy of voltage and internal resistance.

- Convenient parameter setting, lithium battery voltage upper and lower alarm setting, temperature upper alarm setting, current upper alarm setting, voltage imbalance, internal resistance maximum upper alarm setting, SOC initial value set, rated capacity, charger control, etc.

- Main monitoring chip-level real-time Ethernet, 10/100m adaptive LAN interface, the automatic crossover between transceiver and transmitter, can be directly connected to optical fiber LAN (information network/data private network/automatic network, etc.);

- The monitoring software can display real-time AC status, charging state, single lithium battery voltage, internal resistance, and other functions to set multi-level user operation permissions, real-time view alarm information, historical data curve report and print, and other functions.

High consistency is the key, and "equilibrium" is the process to achieve or converge the intrinsic characteristics of the monomer. Some BMS manufacturers, desperately to the balance of current amplification, to meet the domestic low - quality battery applications. It is an urgent matter to improve the quality of domestic electric cells, which not only requires the consistency of the front segment to be done well but also requires the consistency of the rear segment to be excellent. In addition to efficient balance, this is the reasonable and correct development of thinking.

0 comments