Charging speed, energy efficiency and battery life are all factors that make lithium-ion batteries attractive for UPS power applications. Lithium batteries offer several advantages that far exceed the traditional lead-acid batteries commonly used in existing UPS. Longer life, smaller size, lighter weight, faster charging and increasingly lower prices have made lithium batteries a highly sought-after energy storage technology.

Li-ion batteries offer some advantages over traditional lead-acid batteries. Despite their many advantages, the use of lithium batteries in uninterruptible power supplies (UPS or backup batteries) is relatively new to valve-regulated lead-acid batteries, which are still the dominant energy storage technology in common use today. As the cost of lithium batteries continues to fall, their advantages are more widely known, and lithium battery manufacturers continue to build their UPS power more compatible, this pattern is likely to change.

1. what is the difference between lithium batteries and lead-acid batteries?

Lead-acid batteries and lithium batteries have different battery life, nominal voltage, internal materials, energy, and battery selling price. Lead-acid batteries generally have a service life of two years and require frequent replenishment of lead-acid liquid. Lithium batteries, on the other hand, have a longer service life than lead-acid batteries, generally at four years. Unlike lead-acid batteries, lithium batteries are more environmentally friendly and less polluting.

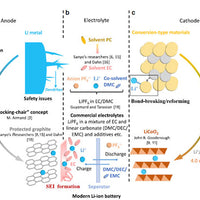

The energy of a lead-acid battery is 30wh/kg, while a lithium battery is 150wh/kg. the internal material difference between lead-acid battery and lithium battery is the positive and negative electrodes of both. When lead-acid battery and lithium battery start to work, both positive and negative electrodes will have chemical reactions, and lithium battery is an organic electrolyte, while the electrolyte of lead-acid battery is concentrated sulfuric acid, and the conductivity of the two materials is different.

The main difference between lithium batteries and lead-acid batteries is the chemical composition of the materials used in the electrodes and electrolyte. Currently, most lithium batteries use metal oxides as the cathode and carbon-based materials as the anode. The electrolyte solution is a lithium salt dissolved in an organic solvent. On the other hand, lead-acid batteries include lead dioxide as the cathode, lead anode, and electrolyte in the form of sulfuric acid.

2. When used in UPS power supply, how to compare the cost of the lithium battery system and lead-acid battery system?

In terms of operating costs, lithium battery systems have a significant advantage. This is primarily because their service life is approximately double (or more) that of a valve-regulated lead-acid battery system. Over the past 15 years, a valve-regulated lead-acid battery system may have been replaced 2-3 times, while a lithium battery may not require any replacement (perhaps once), resulting in significant savings and less maintenance.

Sometimes, lithium batteries have a higher specified cycle life temperature (40°C/104°F) than lead-acid batteries (20-25°C/68-77°F). Therefore, in these cases, they can withstand higher ambient temperatures and still meet their specified cycle life. This can lead to greater savings in operating costs through reduced energy consumption for cooling. The analysis shows that over the past 10 years, the total cost of ownership of UPS power systems based on lithium batteries has typically been 10-40% less than valve-regulated lead-acid battery systems.

3. Does lithium battery have safety hazards?

Lithium batteries have made great strides to become safer and stronger than other commonly used battery types in terms of safety measures. Chemical changes and improvements in battery packaging have made them more stable. Manufacturing processes are mature and the materials used are more durable. Battery management solutions are fully tested and field-proven to prevent lithium batteries from overcharging or overheating. The safety level of lithium batteries is directly evidenced by their extensive use in hundreds of millions of portable electronic devices, smartphones, and electric vehicles.

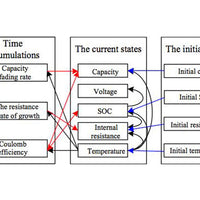

The BMS provides UPS power supplies and users with accurate information on battery status, health, and available runtime. While BMSs make lithium battery systems safer, they also come at a cost to the battery. Because they will increase the cost of the solution and consume battery power, which in turn eliminates or significantly reduces their efficiency benefits compared to lead-acid batteries.

4. I already have a UPS can use lithium batteries?

Assuming the battery system voltage is within the UPS's functional range, existing UPS's can be made compatible by upgrading the UPS's firmware to ensure proper charging procedures, proper runtime calculations, and accurate reporting of charge status. Be sure to contact the UPS manufacturer to determine which lithium batteries are safe and compatible.

5. What is the cycle life of lithium batteries?

For traditional sealed lead-acid batteries, the cycle life is between 200 and 400 cycles. typical lithium batteries used in UPS power applications can reach more than 1,000 cycles. The exact number of cycles depends on many factors, including the specific chemicals used in the design. Currently, some lithium batteries can exceed 5,000 cycles.

6. Does the lithium battery used in the UPS need to be cooled?

When the temperature rises, the cycle life of both lead-acid and lithium batteries will be shortened. Most lithium batteries used in UPS are designed to withstand high average temperatures (e.g., 40°C/104°F) and are capable of reaching their specified life at the high temperatures mentioned. For most UPS applications using lithium batteries, auxiliary cooling is not required to maintain cycle life, but keeping the batteries at a lower temperature (e.g. 25°C/77°F) can help ensure that fully usable runtime is obtained.

7. What is the charge time for Li-ion batteries compared to lead-acid batteries?

The battery charger is usually located in the UPS and controlled by the UPS. In this case, the time to reach 80% state of charge (SOC) is similar. The Li-ion battery is slightly more efficient, so it can reach this level of charge slightly faster. But from 80% to 100% state of charge, LiPo is far superior. Lithium batteries can reach 100% state of charge in 30 minutes to one hour, provided of course that the UPS can supply charging power at the same rate. In any case, it takes 5-10 hours less to charge to 100% than a lead-acid battery system.

Frequently asked questions about the use of lithium batteries in UPS

in Technology

0 comments