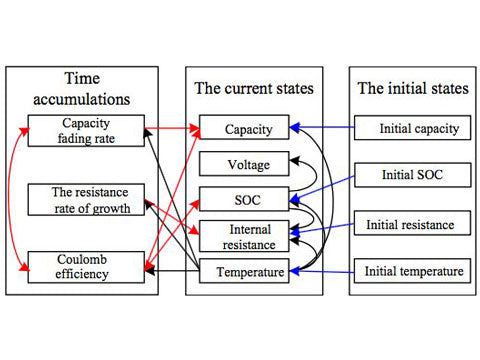

The inconsistency between single-cell Li-ion batteries mainly contains indicators such as temperature, voltage, SoC, capacity and internal resistance, etc. If we take the time factor into account, the inconsistency of Li-ion batteries should also contain self-discharge, Coulomb efficiency, capacity decay rate, etc. These inconsistency factors are divided into three categories: the first category is the initial factors, such as the capacity of the battery, internal resistance, etc. They determine the basic Li-ion battery The second is the present factors, such as capacity, voltage, SoC, etc., and these indicators determine the current capability of Li-ion batteries; the third is the time accumulation factors, such as the rate of capacity decay, the rate of increase of internal resistance and the charge/discharge Coulomb efficiency, and these factors determine the future capability of Li-ion batteries. Once the lithium-ion battery is formed, the "initial state" and "present state" of the battery pack has been determined, we need to address is the "time accumulation factor" on the battery pack performance caused by We need to address the impact of the "time accumulation factor" on the performance of the battery pack.

The impact of the "time accumulation factor" on the performance of lithium-ion battery pack is mainly through the accumulation of repeated cycles, we take the "capacity decay rate" as an example, if two batteries in series A and B, assuming that each cycle of the A battery The average reversible capacity decay rate of battery A is 0.005%, while battery B is 0.008%, the inconsistency of the capacity decay rate of these two batteries will continue to accumulate in the cycle, after 500 cycles, the capacity decay of battery A is 2.5%, while battery Breaches 4%, if there is no equalization protection conditions, battery B because of the reversible capacity decay rate is faster, so in the charging time when battery A After fully charged, the B battery has undergone a significant overcharge, resulting in accelerated capacity decay of the B battery and even triggering thermal runaway of the B battery. The decay rate of Li-ion batteries is significantly higher at the beginning of the cycle than at the end, so the difference in capacity decay rate between A and B may be even greater, and the capacity decay rate will be further accelerated after B battery is overcharged and over-discharged.

The equalization strategies for Li-ion batteries can be divided into two main categories: 1) dissipative equalization; 2) non-dissipative equalization.

The main difference between the two is where the energy of the battery goes during the equalization process. Dissipative equalization restores the balance between single cells by directly discharging all cells to a fixed voltage value, which has the advantage of simple structure, but wastes more energy and has the problem of heat generation. Non-dissipative equalization equalizes the single cells by transferring the power from the higher voltage cells to the lower voltage cells, with the advantage of less energy waste and the disadvantage of more complex structure and higher cost.

0 comments